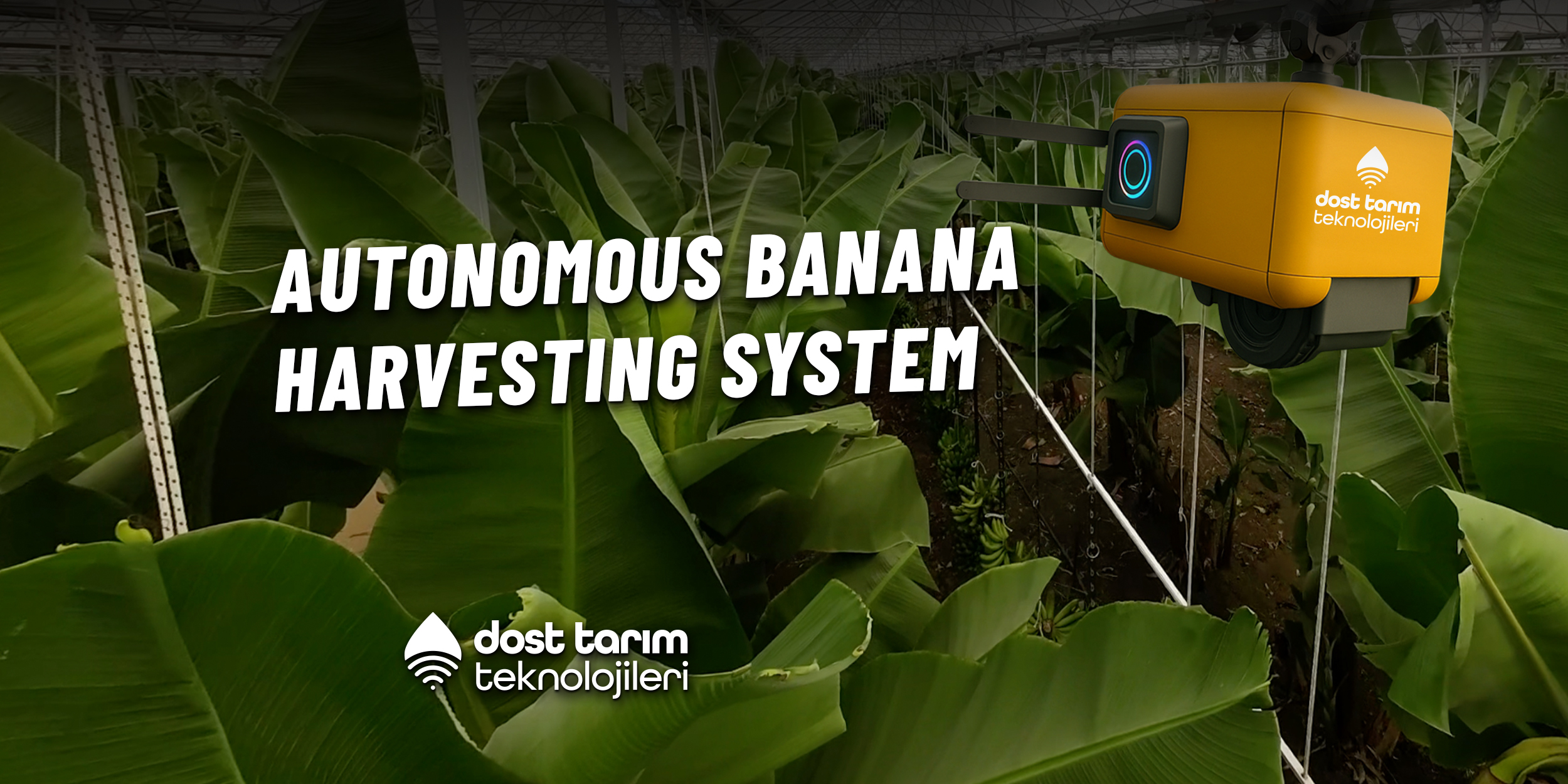

Developed by the engineers of Dost Tarım Teknolojileri, the “ Autonomous Banana Harvesting System ” aims to simplify harvesting and transportation one of the most challenging processes in greenhouse banana production. With integrated image processing technology, it is designed not only as a transport vehicle but also as a smart assistant that protects plant health and monitors crop development.

A Technological Solution to the Physical Challenges of Banana Harvesting

Banana production is a highly demanding process due to humid greenhouse conditions and the damage heavy banana bunches can suffer during transportation. At this most labor-intensive stage, our Dost Tarım Teknolojileri team developed the Autonomous Banana Harvesting System to reduce the physical burden on our workers while also monitoring crop development.

The system moves autonomously (driverless) along rail lines inside banana greenhouses, safely transporting heavy harvested loads and eliminating quality issues during harvest. In doing so, it minimizes the risk of workplace accidents and maximizes operational efficiency.

More Than Transport: Plant Health Under Control

Beyond harvesting, the system plays an active role in the greenhouse. Thanks to the image processing technology integrated by our engineers, it provides:

- Disease and Pest Monitoring: Continuously patrolling the greenhouse, the system analyzes changes in plants through its cameras and detects potential diseases or pests at an early stage.

- Targeted Spraying: With the capability to perform spot spraying in identified problem areas, it helps prevent unnecessary pesticide use, enabling healthier production.

- Data Collection: By gathering visual data from the production area, it provides a digital infrastructure for harvest timing and plant development insights.

Engineering and Agriculture Together

With our Dost Tarım Teknolojileri team, we adopt a needs-oriented approach while integrating technology into agriculture’s natural cycle. The Autonomous Banana Harvesting System eases the heavy workload in the greenhouse while offering precise monitoring to protect plant health.

Aligned with our sustainable production vision, we will continue to advance our operational standards in banana production by utilizing local software and hardware capabilities.